How Apollo Plus Is Using AI to Eliminate Waste in Fashion | Meet the Winner of the Avantex Fashion Pitch 2025

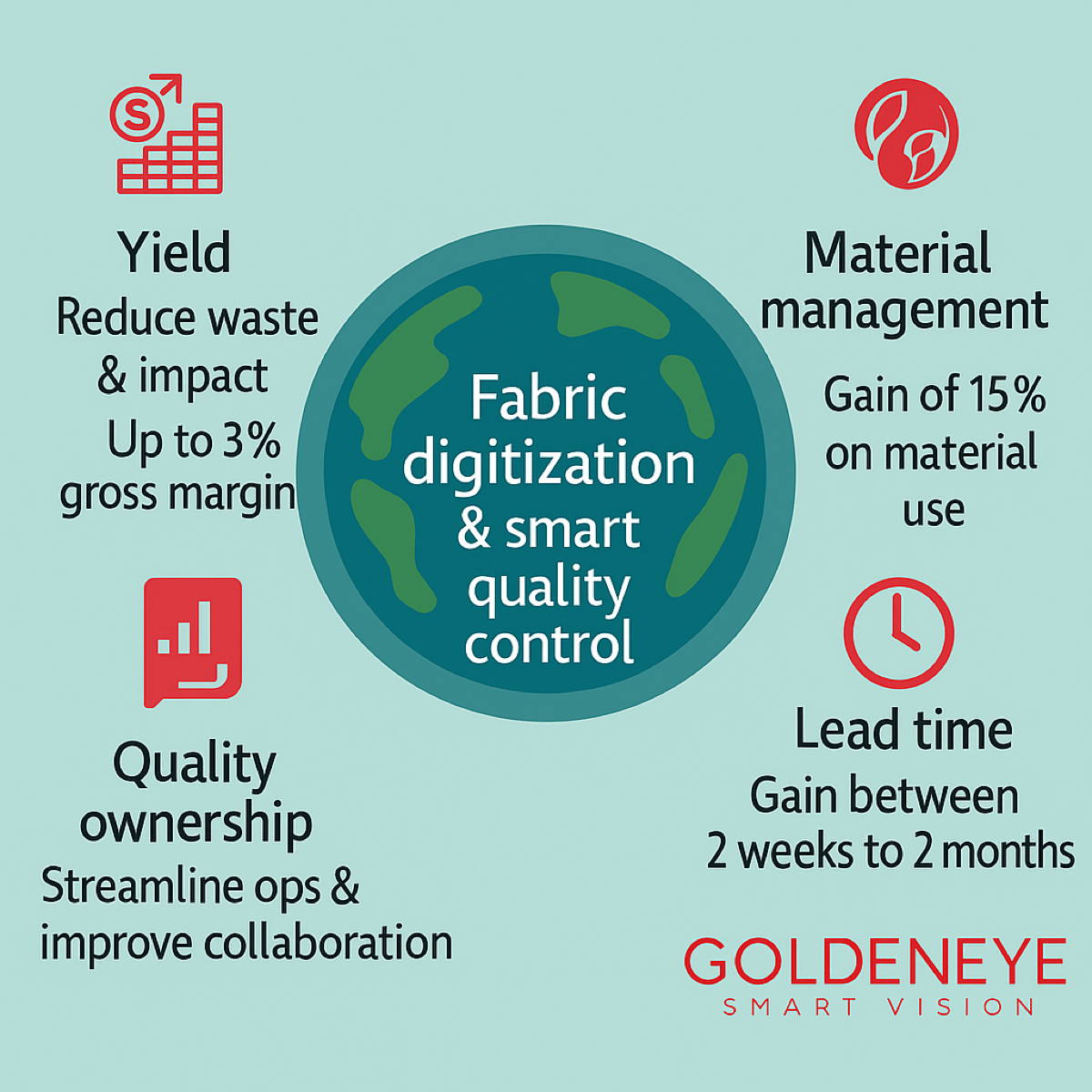

At Avantex Paris 2025, innovation met purpose when Apollo Plus won the prestigious Avantex Fashion Pitch Award 2025 with GoldenEye Smart Vision, an AI system capable of detecting fabric defects with microscopic precision and reducing raw-material waste by up to 15%. Their breakthrough marks a turning point for the textile industry, where artificial intelligence is no longer a futuristic concept but a practical solution for sustainable, efficient, and transparent production. Luxiders exclusively interviews Thomas Isnard, Co-founder and CEO of the company behind this change-maker technology.

With its blend of ultra-high-resolution imaging and self-learning algorithms, GoldenEye transforms traditional quality control into a process that saves time, resources, and emissions. In this exclusive interview, Thomas Isnard, Co-Founder and CEO at Apollo Plus, shares how they’re reshaping the fashion industry — proving that AI can be both intelligent and ethical, accelerating the shift towards a truly circular future.

GoldenEye Smart Vision: Artificial Intelligence for Quality and Sustainability

Congratulations on winning the Avantex Fashion Pitch 2025! What does this recognition mean to you personally and to Apollo Plus as a company?

Winning the Avantex Fashion Pitch is a very special moment for us. Personally, it is the recognition of years of research, resilience, and passion for technology with purpose. For Apollo Plus, it validates our belief that innovation can be both cutting-edge and deeply responsible. It shows that the textile and fashion industry is ready to embrace AI-driven solutions that have a measurable positive impact.

GoldenEye Smart Vision uses AI to detect fabric defects with unprecedented accuracy. Can you walk us through how the system works and why it is such a breakthrough for the textile industry?

GoldenEye Smart Vision is like giving textile machines “a pair of eyes and a brain.” Our system combines ultra-high-resolution cameras with a self-supervised AI that learns directly from fabric patterns. Unlike traditional inspection, which is manual, slow, and error-prone, GoldenEye identifies the tiniest defects in real time during production. This breakthrough means fewer rejected rolls, better quality consistency, and huge savings in raw materials. In short: it transforms quality control from a bottleneck into a competitive advantage.

With a 15% reduction in raw material consumption and a faster time-to-market, how do you see your solution addressing one of the industry’s most urgent challenges: waste reduction and production optimisation?

The fashion industry wastes millions of tons of fabric every year due to undetected or late-detected defects. By catching issues at the source, GoldenEye reduces fabric waste by up to 15% and allows production lines to run faster with fewer stoppages. For brands, this translates into shorter lead times and more sustainable collections. For the planet, it means fewer resources consumed and fewer emissions. We believe sustainability and competitiveness go hand in hand — and GoldenEye is proof of that.

From your perspective, what are the biggest challenges the fashion and textile industry is facing right now when it comes to sustainability and digital transformation?

Two words: speed and scale. Brands are under immense pressure to deliver more collections, faster, while also reducing their environmental footprint. At the same time, most factories are still using outdated processes with limited digitalisation. The challenge is how to scale sustainable practices across complex global supply chains without compromising efficiency. It requires courage from brands to invest in innovation and collaboration across the entire value chain.

“Brands are under immense pressure to deliver more collections, faster, while also reducing their environmental footprint. At the same time, most factories are still using outdated processes with limited digitalisation. The challenge is how to scale sustainable practices across complex global supply chains without compromising efficiency.” – declares Thomas ISNARD, from Apollo Plus.

Looking at the future, what kinds of technologies —beyond defect detection— do you think are most needed to accelerate circularity, traceability, and efficiency in the sector?

I see three priorities. These combined will make “sustainable by design” the new normal:

- Traceability technologies — blockchain or digital passports to ensure every fiber and garment has a transparent story.

- Circularity enablers — AI-driven sorting and recycling solutions that can give fabrics a true second life.

- Process optimisation tools — predictive analytics and digital twins that help factories design, simulate, and reduce waste before production even begins.

Which technological solutions or start-ups have recently impressed you, innovations you think we should all keep an eye on?

I’m particularly fascinated by innovations at the intersection of AI and robotics. Autonomous robots capable of performing complex inspections or handling materials with precision are redefining what efficiency means in manufacturing. Combined with advances in biofabrication and smart textiles — such as fibers grown from agricultural waste or fabrics with embedded sensors — these technologies have the potential to make production both more intelligent and more circular. What excites me most is how AI-driven automation can become the backbone of a fashion industry that is faster, more transparent, and radically less wasteful.

Many in the industry still see AI as “complex” or “abstract.” How would you explain, in simple terms, why it’s a practical tool for making fashion more sustainable and profitable?

AI is simply a tool to see better and decide faster. Imagine having a super-skilled quality inspector who never gets tired, never misses a detail, and can analyze data from thousands of fabrics at once. That’s what AI does: it saves time, saves resources, and helps humans focus on creativity instead of repetitive tasks. For the fashion industry, it means less waste, better quality, and more sustainable growth.

Beyond the award benefits, what opportunities do you hope to unlock with the visibility gained through Avantex, Messe Frankfurt, and the Circular Textile Days keynote?

Visibility means connection. We hope this recognition will open doors to new collaborations with textile manufacturers, brands, and sustainability leaders worldwide. It is also a chance to attract industrial and financial partners who share our vision: scaling GoldenEye to make defect-free, waste-free production the standard across the industry.

Is Apollo Plus currently working on developing or integrating new technologies beyond GoldenEye Smart Vision to further support manufacturers and brands?

Yes. GoldenEye is our flagship, but our roadmap is broader. We are working on solutions that leverage AI and data science to optimise production planning, energy efficiency, and even predictive maintenance for textile machinery. Our goal is to create a full suite of tools that empower factories to become not only more profitable, but also truly sustainable.

Finally, what is your long-term vision for Apollo Plus? How do you see your company shaping the future of fashion technology in the next decade?

Our long-term vision is bold: we want to become the reference partner for sustainable industrial AI in fashion. In the next decade, Apollo Plus will expand beyond defect detection to cover the entire textile value chain, from fiber to finished garment. By combining data, AI, and sustainability, we aim to help build a future where fashion is not only creative and desirable, but also efficient, transparent, and respectful of our planet’s resources.

“By combining data, AI, and sustainability, we aim to help build a future where fashion is not only creative and desirable, but also efficient, transparent, and respectful of our planet’s resources.”

Images:

@ Courtesy by Texworld Apparel Sourcing Paris