5 New Sustainable Design Materials

One hundred billion plastic bags are sold in the European Union every year, according to a 2013 report from the European Commission. Up to 8 billion of these end up as litter.

Plastics do not degrade naturally in water or soil and therefor cause major harm to animals and ecosystems. To address the ecological disaster of plastic pollution, new materials that are more comparably sustainable to previous ones are being developed for new and existing products.

As concerns progress about climate pollution and the destruction of our natural environment, so are more products on the market being labeled “sustainable”, “biodegradable”, “compostable” and “circular”. It seems the conversation of change has gained traction in the world of furniture design. Recent years have shown innovation in green material developments in response to a rise in consumers who desire a deeper significance in their material products — a characteristic traditionally afforded by luxury brands.

In the age of global conservation, we are facing a readjustment of what we consider Luxury. The future of luxury materials will be defined and measured not just by the aesthetics or origin, but by understanding the true value of materials within a greater holistic narrative, with sustainability driving all aspects of the process — from production, application through to distribution. We selected five new innovations in industrial materials that you will start to see more and more of.

Mushroom Mycelium

Nir Meiri founded his studio Nir Meiri Design Studio in 2010, setting out to approach designing everyday objects with a remarkable philosophy. “Nothing lasts forever, we humans also age over time and I believe that products should also be able to ‘age’ as this is nature’s call.” Meiri explains,

“We believe in a life-cycle and once a product reaches the end of its life it should be able to decompose and return to life as something else.”

His inspiration comes from nature. Meiri carefully selects materials, often raw and wild to create innovative products that play on the tension between the domesticated and the untamed. Meiri explained, in developing “natural materials we believe that the process is as important as the final result.”

In collaboration with London based startup BIOHM, Meiri developed a new method of mixing the vegetative part of the fungus in mushrooms called Mycelium with metal. This material can be used for building and manufacturing. The organic result was an extraordinary collection of table lamps that resemble qualities of wild mushrooms while maintaining an overall captivating minimalism. Meiri describes his new material as taking on its own form as it consumes organic and authentic waste. This process creates the textured surface of his furniture. Mycelium has a suede-like surface that can provide a soft touch when paired with firm materials such as stone, wood or steel.

Chip[s]Board

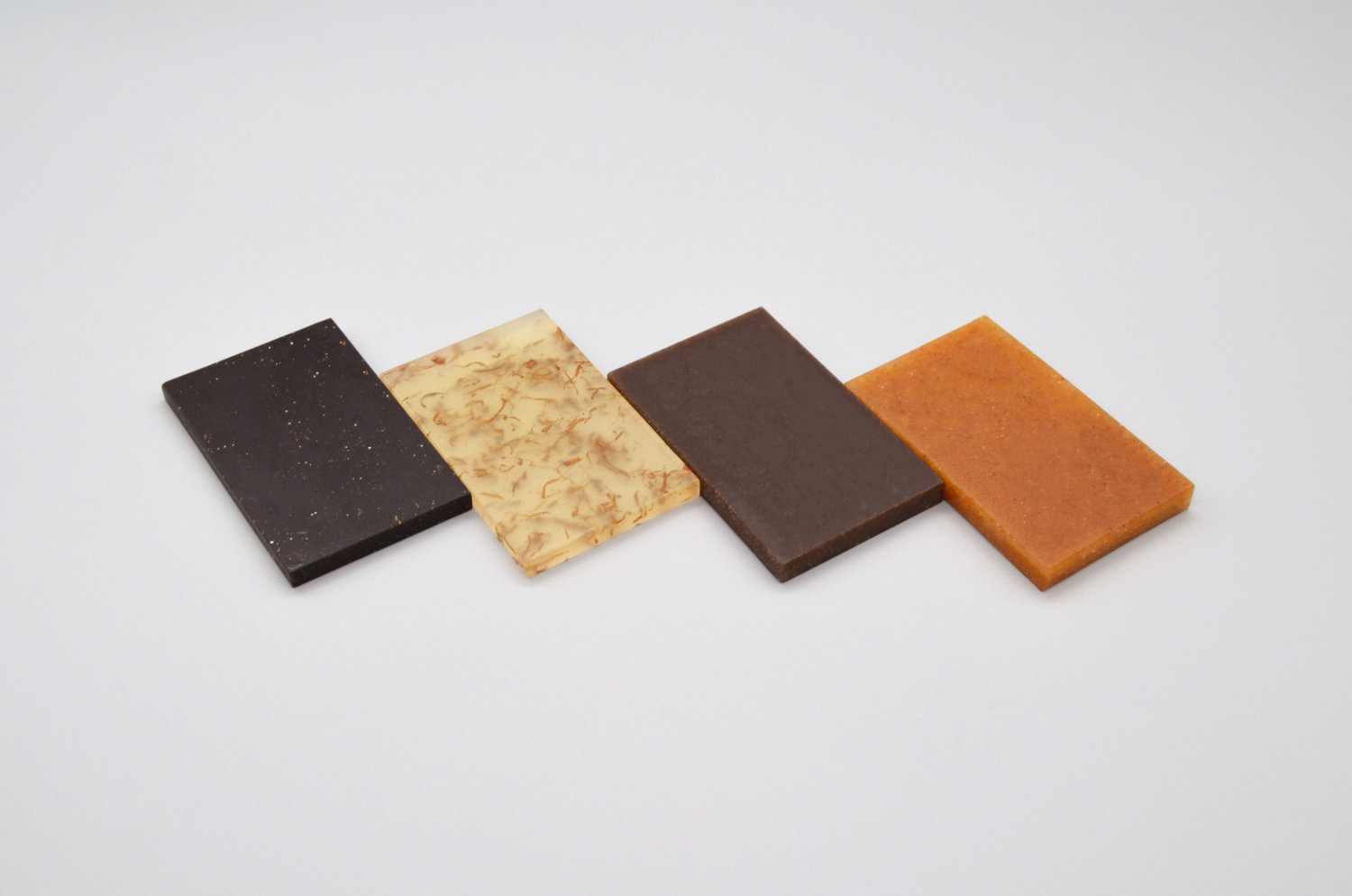

Rowan Minkley and Robert Nicoll created the green alternative to single-use materials like chipboard and medium density fiberboard (MDF). Their product called Chip[s]Board uses non-food-grade industrial potato waste to produce bio-plastics and bio-plastic composites called Parblex™. While other biobased materials are being developed, no other bioplastic manufacturer is using agricultural-food waste. Existing bioplastics produced by companies such as NatureWorks or TotalCorbion are produced from harvesting virgin food crops, e.g. corn or sugar beet.

Compared to petrochemical plastics, this material is non-toxic, biodegradable, has low impact from manufacturing, and doesn’t involve mining for oil in nature reserves. Their company was founded on the core principle of a circular economy with a sustainable business model that deals with material production through waste management using abundant resources we currently have rather than continually processing virgin materials.

“Materials often need short lives, so our vision is to create materials that work with the cycles of nature not against it.”

(Rob Nicoll, CPO & co-founder of Chip[s]Board)

The process of turning potato waste into a usable and durable material involves using a binding agent extracted from raw potato peel that is applied to potato skins, bamboo, recycled wood and beer hops. The final mixture is pressed into shape using heat, to shape a robust wood substitute that can be used in an array of furniture, wearable products and architecture. At the end of its life-span, the Chip[s]Board material can be fully composted back into fertilizer.

Solidwool

Driven by the decline of wool manufacturing in their home town of Buckfastleigh, Justin and Hannah Floyd started the company Solidwool to find new ways of working with sustainably sourced wool, a strong and visually tactile material that can be used in furniture production.

Solidwool is a more sustainable composite material that was showcased at this years designjunction. This material is made of layers of compacted coarse, low-value British wool that would otherwise be thrown away. An epoxy-based bio-resin is used to seal the layers into a durable material that similar to fiberglass.

Their design of the Hembury Chair is made with Solidwool and focusses on classic, simple shapes to allow the beauty of the material to stand out. Inspired by the Eames Plastic Side Chair, originally manufactured using Fibreglass in the 1950s. This classic design is re-imagined with their unique material.

Flax Fiber

ProjectFlax was an international research project explored by 20 national and international, commercial and institutional flax researchers funded by the European Union. The findings delivered new innovations in industrial production methods and novel applications of sustainable materials for human and environmental wellbeing. Flax was the unexpected plant source which produced premium products and textiles.

Flax is biodegradable and can be grown in cold climates or off season. This allows for increased crop rotation and helping farmers use less land which can help to alleviate deforestation. Flax also grows quickly and needs less irrigation, pesticides and herbicides, which will help stabilize local water sources.

Branded the first sofa for the circular economy, the SofaForLife is made from renewable materials that have been chosen to extend its lifetime to the maximum, as well as enable repair, reuse and re-manufacturing. Saskia Goeres, the founder, spent over a year developing the product to make sure it embeds circular economy principles in every aspect of its development. Their process produces around 90% less Carbon emissions than traditional manufacturing methods.

The frame has been made from European birch plywood — a fast growing hardwood chosen for its local availability. The cushions covers use sustainable patina fabrics combining wool and flax fibers. These fabrics are machine washable and are EU Eco Label Certified. The cushions are supported with layers of coconut coir to provide a firm and sturdy base, and are topped with a layer of Comforel, a material made from recycled plastic bottles. At the end of its life, the sofa is designed to be disassembled into its material components, which can be reused or recycled.

Jesmonite

The London Design Fair named Jesmonite the material of the year in 2017. Invented in 1984 in the UK, Jesmonite is an acrylic-modified gypsum composite that has a wide range of aesthetic capabilities. Jesmonite is a type of eco-resin that can be used as an environmentally friendly substitute for polyester GP resin because of its water-based and non-toxic properties. It was originally adopted by architects and builders for its lightweight and versatile properties but is now a popular choice among designers and sculptors alike.

London based designer Ariane Prin has designed a collection of oxidized and corroded pots, trays and vases made using reclaimed metal dust. Prin’s RUST collection is inspired by the desire to create new form and utility out of commonly disregarded waste materials. Her method involves mixing metal dust, plaster and water-based resin Jesmonite to form a material that sets in sedimentary layers. As the metal dust slowly oxidizes, it produces a special pattern on the surface of the vessels.

The process is stopped with a water-resistant coating and the chemical reaction leaving a copper gradient finish.

Prin’s luxury homewear range demonstrates an innovative method of reusing waste materials. The RUST collection is composed of plant pots, trays, fruit bowls, vases and jewellery boxes created by mixing metal dust with plaster and eco-resin. No two items in RUST are the same: the collection is entirely hand-made and the metal dust oxidation gives each product a unique texture, varying in colour and intensity.