Is 3D Printing The Future Of Sustainable Architecture?

Could you imagine your future home coming from a printer? 3D printing is revolutionising how we build our houses. Projects all around the world are adopting the technology to offer affordable, sustainable solutions for our homes and buildings. Is it a scalable solution? How far can 3D printing go in architecture? Find out more!

Scientists in Zurich estimate that the construction sector is responsible for “40% of global energy consumption, 38% of global greenhouse gas emissions, 12% of global potable water use, and 40% of solid waste generation in developed countries.” With growing concerns for eco-friendly buildings, 3D printing might just be the solution that revolutionised other industries, like fashion and design. The change now takes over construction, drastically changing the amount of time and cost of building a house. It is hard to grasp the idea of an entire house being built from a printer. Here, we explain how 3D concrete printing works and how far it can go.

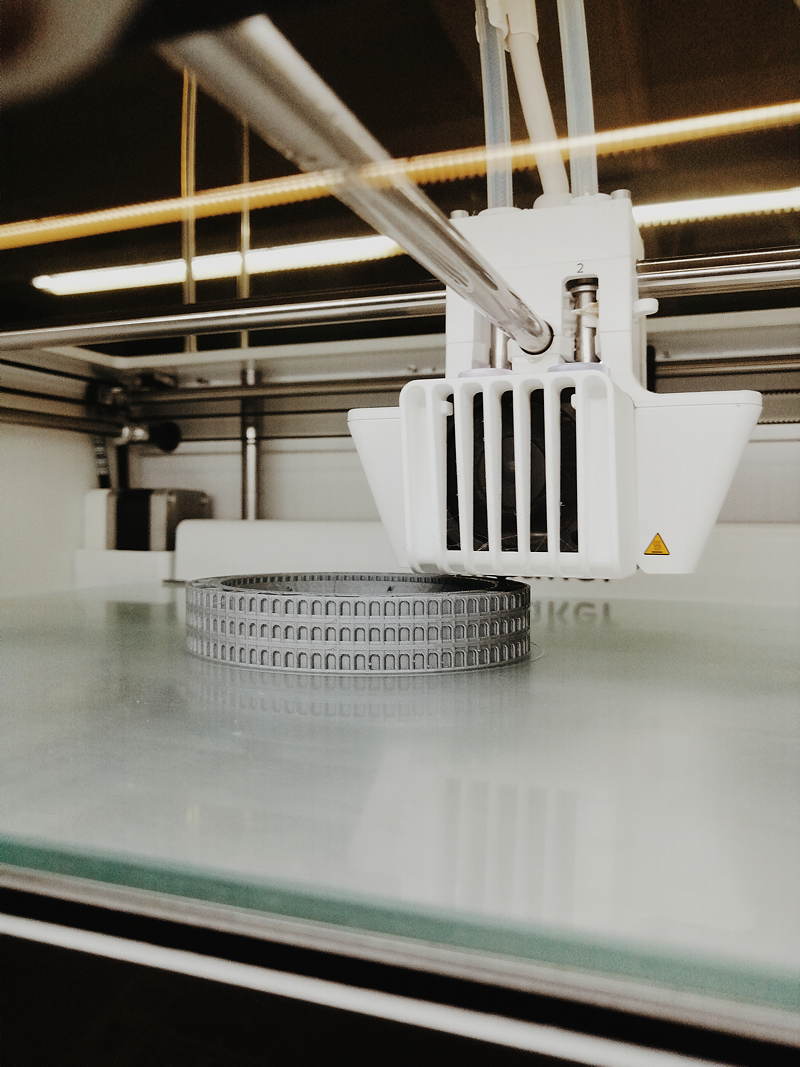

HOW DOES 3D PRINTING WORK?

Initially, 3D printing focused on plastic materials, but advancements have expanded its capabilities to include glass, metals, and now concrete for constructing houses. Concrete 3D printing involves a layering process using a large printer equipped with a robotic arm. One end of the arm is attached to the printhead, which dispenses the building material, while the other end is connected to a system analogous to a crane, allowing for movement. The printhead nozzle releases a mixture of cement, sand, and other specialised additives, layering them to form walls.

A SUSTAINABLE SOLUTION

Traditionally, slow, labour-intensive tasks that can be a hazard to sustainability characterised the construction sector. Nevertheless, 3D concrete printing presents a potential opportunity for quicker, more accurate, and environmentally friendly construction methods. First, it reduces the time and labour required. ICON, a pioneer in 3D printed architecture, highlights that its proprietary Vulcan technology can be set for printing within an hour with a four-person crew. The team prints the walls in less than two weeks, minimising the time, waste, and cost of traditional construction methods.

Initially, 3D printing in construction involved prefabricated materials offsite. However, with the advent of industrial 3D printers, all components can now be printed directly at the construction site. It streamlines the logistic process by reducing the need for transportation and intermediaries. Additionally, 3D printing is highly reliable and precise, enabling the optimization of materials and generating minimal waste. The technology also has the potential to reduce the carbon footprint of the construction industry and result in less water-intensive processes.

While buildings constructed with 3D printing are durable and built to last, the use of concrete as a primary material presents sustainability limitations due to its carbon-intensive nature. However, the flexibility of 3D printing technology allows for the use of a variety of materials. Research from India suggests that in the future, we could see the adoption of construction methods using recycled plastic, biodegradable, or other eco-friendly materials.

HOW FAR CAN 3D PRINTING GO?

Nikita Cheniuntai, Founder of Apis Cor, clarifies that when people refer to “printing a house,” they are specifically referring to the process of 3D printing the walls of a building. At present, the printer is not involved in constructing other parts of the house, such as the foundations and roof. Additionally, 3D printers have limitations on the maximum height of buildings they can construct, which currently restricts most projects to single-story structures. Introducing 3D printing to areas with uneven terrain can also pose a challenge. However, companies like Apis Cor are actively working on developing solutions to bring 3D printing technology to more challenging environments and eventually achieve fully printed houses.

We should also remember that we are talking about a giant printer that is not easy to transport or assemble. To become a scalable project, Cheniuntai suggests that we need to create a “low-cost, functional 3D printer that can work in complex operating conditions”. The other gap we need to fill is education. 3D printing is a new tool that needs people to know how to operate it. Investing in research and education to simplify the processes and teach people how to use it are key to making it a more global project.

NEW PROJECTS ARE PAVING THE WAY

Building for Humanity is leading one of the biggest printing projects in Europe. In partnership with HTL, the organisation will create 46 high-quality, affordable homes for low-income families, veterans, and others in need. The houses in Lancashire, United Kingdom will be sustainable, net-zero carbon buildings. It will also involve energy-efficient and environmentally friendly technology.

Correspondingly, ICON, in partnership with Lennar and architecture firm Bjarke Ingels Group, is creating the world’s largest neighbourhood of 3D-printed homes. The project in Texas is a 100-building community. In the summer of 2023, the project showcased the first finished house. It has an elevated, yet minimalist design for comfortable living. Everything in the project is printed on-site.

Similarly, inspired by projects in the United States and China, architects in Germany also built the first 3D-printed house in the country. The project earned the firm Mense-Korte Ingenieure+Architekten the German Innovation Award. China is taking the ambition of 3D printing to new levels, planning to 3D-print a 180-metre-tall dam. The building would become the biggest 3D-printed structure.

3D PRINTING CAN BE LUXURIOUS

ICON also demonstrated the reach of 3D printing with its first exploration into luxury housing, House Zero. The modernist design by the eco-conscious firm, Lake|Flato is elegant, yet cosy. Located in Austin, Texas, it spans over 185 square metres and features three bedrooms and two bathrooms in the main house. The common areas are gracefully dynamic and offer a relaxing setting. While preserving the ranch-style aesthetic, the energy-efficient elements are a testament to the 3D printing vision of sustainability. They complemented the house with other materials to elevate the atmosphere. In other sections, the designers left exposed concrete walls to give a refreshing contrast.

The design of House Zero seeks to incorporate natural elements into the built environment to enhance its connection with humans. For example, the strategic placement of windows and doorways highlights the surrounding landscape and maximises the entry of natural light during the day, which reduces the need for artificial lighting. Additionally, the curved walls of the house improve its structural stability and create more natural and fluid pathways within the interior. The use of 3D printing enables creative forms that would be challenging to achieve with traditional construction methods. The house was named one of TIME’s Best Inventions 2022 in the Design category.

Highlight Image:

© Daniel McCullough via Unsplash

+ Words:

Francesco Witt

Luxiders Magazine