Seeking the Natural Beauty | Interview with Lena Franz

As concerns over sustainability in the cosmetic industry increase, some brands pave the way to reach natural and sustainable beauty. We asked Lena Franz of Team Dr. Joseph about how they experience the sustainable revolution of beauty.

To receive the Luxiders Newsletter, sign up here.

It is an undeniable fact that cosmetic products keep a remarkable place in our lives. For healthier skin, shinier hair, an impressive scent, and better mental health through beauty routines, we welcome these products to our houses. However, it is important to ask if they are good for our skin through clear formulations and sustainable, considering the production phases and their impacts on the planet. Unfortunately, many cosmetics brands in the beauty industry have adopted unsustainable practices where they include problematic chemicals in their formulations. Even some organic ones cause deforestation through overharvesting of the natural substances. Therefore, we wanted to ask a prominent figure; an inspirational sustainable cosmetics brand, Team Dr. Joseph about how they conduct their practices on reaching sustainable beauty. Lena Franz, Head of Sustainability at Team Dr. Joseph, and the daughter of legendary founder Dr. Joseph have answered our questions. Here is a fascinating interview where Team Dr. Joseph paves the way to be sustainably beautiful.

L: The industry relies heavily on various ingredients, some of which may be obtained from unsustainable sources. For instance, certain plant extracts and oils may be obtained through deforestation or over-harvesting, which can harm ecosystems and biodiversity. Promoting responsible ingredient sourcing, such as using sustainably grown or ethically sourced materials, is crucial for long-term sustainability. Do you think this is being done sufficiently in the industry? What is the most sustainable solution for you?

LF: While there are some positive examples of sustainable practices in the cosmetics industry, overall it is unfortunate to note that the industry still has a long way to go. Many companies still rely on unsustainable sources for their ingredients and there is often a lack of transparency, making it difficult for consumers to make informed choices. The most sustainable solution is a combination of responsible sourcing of ingredients and innovative technologies. Close cooperation with suppliers is essential to promote sustainable farming practices and improve working conditions. At the same time, new technologies such as biotechnology can help to significantly reduce the impact on our ecosystems from the use of microorganisms to produce active ingredients. In addition, the industry must increasingly rely on alternative, environmentally friendly ingredients. There are a variety of plant-based, biodegradable alternatives to many common synthetic ingredients. Finally, consumers play a crucial role. By making conscious choices to buy products that are sustainably and responsibly produced, they can encourage the industry to improve its practices. To make sure that products deliver what they promise, labels for certified natural cosmetics offer good guidance. The criteria for genuine natural cosmetics cover all aspects of the sourcing, production, marketing and control of cosmetic products.

L: Many cosmetics and skincare products contain chemicals that can be harmful to human health or the environment. This includes ingredients like parabens, phthalates, and certain fragrances. Do you think there is a possibility to create products that have longer shelf lives without using paraben and silicone? If yes, how?

LF: Yes, it is absolutely possible to develop long-lasting products that do not contain parabens and silicones. While there is a long list of approved preservatives for conventional cosmetics, which are not always without undesirable skin irritations, natural cosmetics completely avoid synthetic preservatives. Instead, pure organic alcohol or essential oils are often used to preserve natural cosmetics.

We at TEAM DR JOSEPH have developed our own preservation system that works without alcohol. We use a combination of different natural oil fractions which prevent the oxidation of the products and at the same time protect the skin barrier. In other words, the preservation system of our products not only provides excellent protection for the cosmetic but also for the skin.

In addition, we use osmotically purified mountain spring water for our products. We use the principle of reverse osmosis to purify our water. This physical process which reverses the natural osmosis process by equalising pressure, makes it possible to obtain very clean and pure water. This enables us to reduce the use of preservatives in the formulation process to a minimum. After all, the cleaner the water (and the raw materials), the less preservation is necessary. In addition, other factors such as correct storage and use play an important role in the shelf life of the product.

L: Historically, the cosmetics industry has relied on animal testing to ensure product safety, which raises ethical concerns and animal welfare issues. Do you think the cosmetics industry is using word tricks in this sense, confusing cruelty-free with vegan, a word that is also wrongly associated with sustainability?

LF: Yes, there is definitely a risk of these terms being misunderstood or manipulated. It is important to stress that "cruelty-free" and "vegan" do not mean the same thing. A "cruelty-free" product simply means that no animal testing was done in its production. A "vegan" product, on the other hand, contains no ingredients of animal origin, but in no way excludes animal testing in its manufacture. However, none of these terms automatically guarantees that the product is sustainable or natural. The cosmetics industry, like many other industries, likes to use marketing terms that give a positive impression at first glance but can be misleading on closer inspection. This is especially true when it comes to terms like "sustainable", "natural" or "green". It is important that consumers are aware that not all "green" claims are the same.

Management Team of Team Dr. Joseph

L: What do you think about alternative testing methods, such as in vitro testing and computer modeling, can they help reduce reliance on animal testing and promote more sustainable practices?

LF: Animal testing of cosmetics and cosmetic ingredients has been banned in the EU since 2013. However, there are two regulations for cosmetic ingredients in the EU that contradict each other. The conflict between these two regulations is that the European Cosmetics Regulation prohibits the use of animal testing in the cosmetics industry, while REACH requires animal testing for the safety assessment of chemicals in certain cases. To address this issue, there are efforts to develop and promote alternative testing methods that can reduce or replace the use of animal testing. For example, in vitro testing and computer modelling have great potential to reduce the need for animal testing. Instead of relying on animal testing or clinical trials, virtual models and simulations can be used to cover certain aspects of product development and evaluation.

In vitro testing, where human cells or tissues are tested in the laboratory, can give a better idea of how human skin or bodies react to certain ingredients. Computer modelling, on the other hand, uses advanced algorithms and biological databases to simulate the effects of chemicals on the human body. These technologies are still in development but are already showing promising results. Not only can they reduce reliance on animal testing, but they can also help promote more sustainable practices by using fewer resources and producing less waste. It is crucial that industry continues to support and invest in these alternative testing methods to enable the transition to more ethical and sustainable practices.

L: Cosmetic products often contain non-biodegradable components, such as plastic containers or microbeads, which can be challenging to recycle or dispose of properly. Do you think bio-sourced plastic packaging or refillable packaging will take us to a more sustainable beauty care?

LF: Biodegradable or refillable packaging can definitely help reduce the environmental impact of the beauty industry. However, a look inside the jar should also be taken in this context. The primary raw materials of conventional cosmetics still consist of petroleum derivatives, which can not only be harmful to the human organism but are neither derived from renewable raw materials nor biodegradable. Instead of synthetic microbeads, we use biodegradable jojoba seeds or fruit acids and natural enzymes for our peelings, for example, to achieve the desired peeling effect.

L: What do you think about glass as packaging?

LF: Glass as a packaging material offers many significant advantages for our environment, despite some disadvantages, such as its high weight and increased risk of breakage. All the elements needed to make glass, such as sand and limestone, come from natural sources. In addition, glass is 100% recyclable and can be reused or refilled as often as desired without losing quality. Furthermore, glass is considered the most stable of all packaging materials due to its inertness and impermeability. This means there is no risk of harmful chemicals coming into contact with the product because, unlike other packaging materials, glass does not require any additional barrier or additives to secure the contents. Finally, when using new glass, the proportion of waste glass can be as high as 90%. This significantly reduces the carbon footprint and further underlines the sustainability of glass as a packaging material. Despite its disadvantages, glass thus proves to be an environmentally friendly and safe option for packaging products.

L: Are there any innovative recycling technologies you are implementing at Team Dr. Joseph?

LF: In general, we make sure to use 100% recyclable packaging and prefer packaging made from already recycled materials. For example, our outer cartons are made of 100% recycled paper. We also try to keep our use of plastic to an absolute minimum and offset anything that cannot be reduced through our partnership with Plastic Bank®, which establishes recycling ecosystems in countries that lack adequate waste management infrastructure and where pollution and poverty are widespread. Residents of these regions can collect plastic from their surroundings and bring it to their local Plastic Bank to exchange for money, fresh food, clean water, mobile phone services, cooking oil or even school fees for their children. The collectors receive a premium in addition to the market value of the plastic, which provides them with a stable income. Through this partnership, we ensure that for every gram of plastic we put into the market, the same amount is recovered from the ocean and nature and recycled.

Team Dr Joseph ©

Team Dr Joseph ©

L: The energy-intensive nature of manufacturing processes, transportation, and packaging in the cosmetics industry contributes to greenhouse gas emissions and climate change. Do you think cosmetics brands are transparent here? Should they inform the customers about how do they save energy?

LF: Unfortunately, the transparency of many cosmetics brands regarding their energy-intensive processes and associated greenhouse gas emissions is often insufficient. Many companies do not disclose whether they take measures to minimise their energy consumption or offset the associated emissions. As a certified carbon neutral company, we record our CO² emission sources, analyse them and update our balance annually to gain better control over our emissions. In addition, all our energy consumption comes from renewable energy sources and we offset our annual CO² emissions through carbon offset projects, all certified to the highest international standards and verified by independent third parties.

L: The production of cosmetics and skincare products requires significant amounts of water, both for ingredient cultivation and manufacturing processes. Implementing water-efficient practices and exploring alternative manufacturing methods can help reduce water consumption. What are the challenges here and what Team Dr. Joseph’s proposal to fight them?

LF: One of the biggest challenges in reducing water consumption in the cosmetics industry is the dependence on water-intensive agricultural practices for sourcing raw materials. In addition, the manufacturing processes themselves often require large amounts of water. One approach to solving this problem is the use of biotechnologically produced active ingredients. By using microorganisms such as bacteria or yeasts to produce active ingredients, considerable amounts of water can be saved. In addition, biotechnological approaches have the advantage of being less dependent on climatic conditions and thus being able to guarantee consistent quality and availability of active ingredients. However, it is important to emphasise that biotechnological processes alone cannot solve the problem of water consumption in the cosmetics industry.

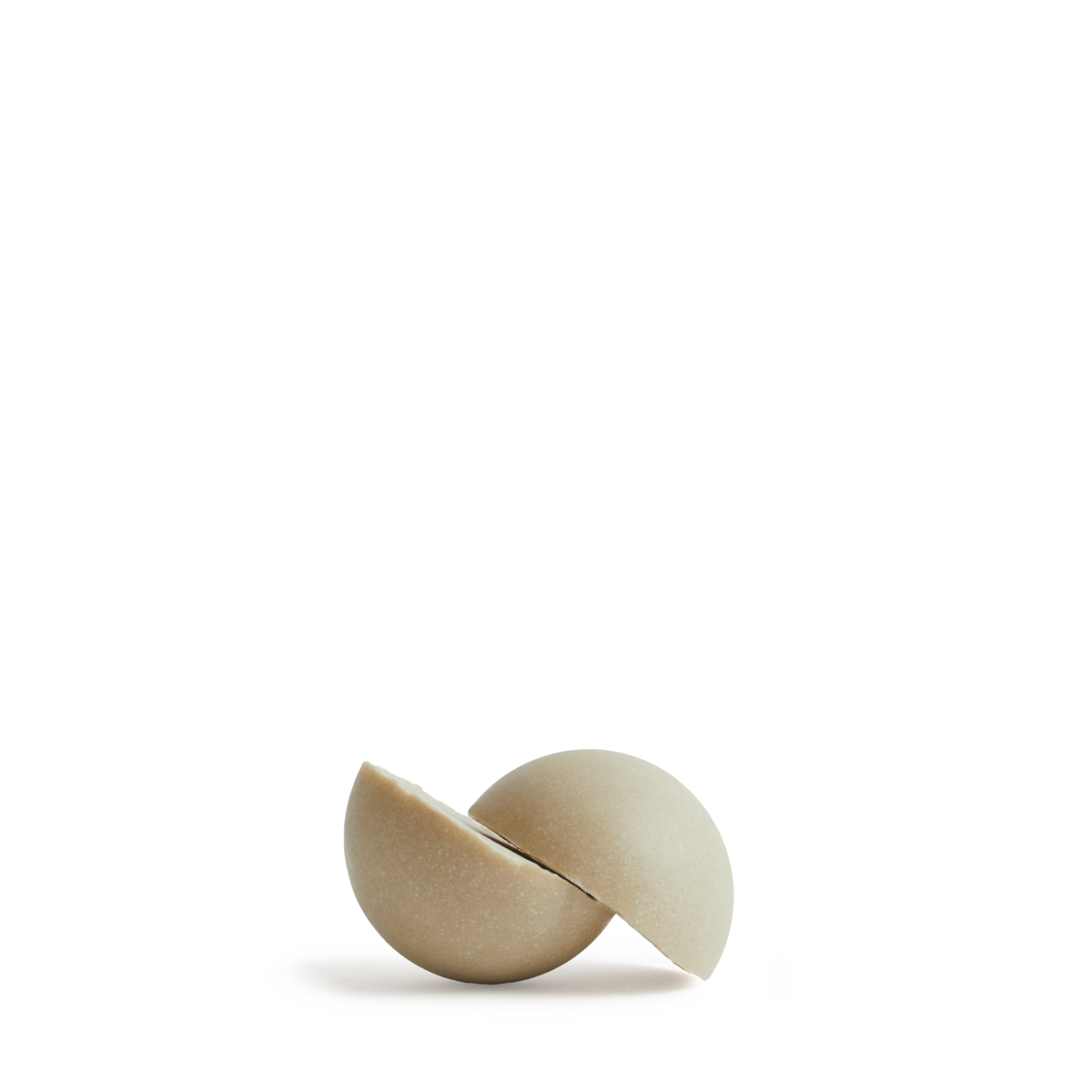

A comprehensive approach is necessary, including improved efficiency in production processes and a more conscious use of water resources in general. Since many cosmetic products consist to a large extent of water, there are other approaches to reduce water consumption here as well. For example, our "Solid" products (Gentle Hand Wash, Super Soft Hair Wash + Balm, Refreshing Body Wash) do not use water in the formulation at all. Furthermore, instead of water in our formulations, we use different flower waters, which not only have a wonderful effect on the skin but are also created as by-products during the distillation of essential oils. Another relevant factor is also the choice of production location. We are in the fortunate position in South Tyrol that the zone is not affected by water scarcity and can thus produce our products with Alpine spring water.

Solid Body Wash by Team Dr Joseph ©

Solid Hand Wash by Team Dr Joseph ©

L: Can you tell us a little about the most sustainable Team Dr. Joseph product?

LF: In general, all our products are sustainable as they are certified organic, 100% recyclable, made in South Tyrol and rich in biotechnological ingredients. One particularly sustainable line is our solid cleansing products - a set of solid shampoo, body wash and hand wash that use no water at all. Instead, we rely on high-quality and 100% natural ingredients to create these products that cleanse and condition hair and scalp without synthetic additives, fragrances or silicones. The compact size and light weight not only reduce the amount of waste, but also require less space to transport and can avoid further CO² emissions due to their lighter weight. In addition, the shampoo bars can be used more sparingly due to their concentration and solid form. In addition, the products are handmade in South Tyrol, are certified organic, vegan, and biodegradable.

Solid Shampoo by Team Dr Joseph ©

Interview:

Tolga Rahmalaroglu

Luxiders Magazine Contributor