Reality Behind the Denim Industry | Interview with Rebecka Sancho

From garment production to the washing stage, despite its huge popularity, the denim industry is responsible for a significant amount of pollution and water use. We asked Rebecka Sancho from G-Star about how to achieve a sustainable denim industry.

To receive the Luxiders Newsletter, sign up here.

When Y2K started influencing our lives, we all witnessed several changes in fashion: Low-rise jeans, baby tops, and the rise of the color pink. However, what the 2000s brings else is definitely the double-denim trend. All the influencers, trendsetters, and most of the fashion houses show up with denim pieces nowadays – and this is not only because this garment is trendy, but denim has always been an ‘it’ piece. It is timeless, it is easy to create stylish looks with denim, and it might be the most essential part of post-industrial fashion. Despite this quite anticipated position of denim, the reality behind its production can be very cruel and harmful to the planet. Huge amounts of water use, water pollution in the indigo dying process, and unhealthy working conditions during the sandblasting technique result in denim being produced unsustainably. This is why we asked Rebecka Sancho from G-Star to tell us how they keep their accountability on being sustainable and what denim leaders should consider when producing these beautiful garments.

Rebecka Sancho, Head of Sustainability at G-Star RAW, did her master’s in Sustainable Development at Utrecht University. Focusing on sustainable product strategies, factory improvements, and environmental sustainability; Sancho values innovation in the industry a lot. As G-Star is committed to using recycled, organic, bio-based, and compostable materials to 100% by 2030, here is an interview with the person who is highly active behind these sustainability plans.

Rebecka Sancho

L: We all know the denim industry is known for its widespread pollution and negative environmental impacts, which are caused by various factors including the use of toxic chemicals, excessive water consumption, and energy-intensive production processes. What is your company doing to solve these factors?

RS: There’s no denying that the fashion industry is a polluting industry. But people will continue to wear and buy clothes, so the importance lies in discovering how to do things better and scaling it across the industry. Ever since 2006 we have realized our responsibility towards people and the planet and started to integrate sustainability more and more holistically into the core of our business and throughout our value chain. We have policies and targets in place, measure current status and act to reduce any negative impact.

A few examples of our goals and how we work on achieving them are:

In 2023 we will only work with organic, recycled, regenerative, bio-based, and compostable materials.

- Last year, we joined Organic Cotton Accelerator. Being a denim company, we believe it is our responsibility to support sustainable agriculture practices. Through this partnership, we aim to support and scale organic cotton farming, so that not only we can meet our targets, but the entire industry can move towards using more sustainable materials. And because of OCA’s ambitious Textile in Transition project, we can now build direct contact with the farmers, improving livelihoods and tracing our organic cotton right back to its roots.

By 2030, at least 1.000.000 G-Star jeans will be re-used, repaired or recycled.

We are constantly building on and extending our end-of-life phase initiatives:

- If your jeans have lost a button or have a hole or a tear, you can get them repaired at our Certified Tailors, on us.

- As of this Summer our customers will be able to trade-in and buy second-hand G-Star garments on G-Star.com

- If your denim is beyond re-selling or repairing, you can hand them in at our stores for proper and responsible recycling.

Continuously build on and improve the collaboration with our suppliers:

- We recently hosted a two-day supplier conference, where we invited all our suppliers to our HQ office for alignment on strategy and to further improve collaboration. They are pivotal for us when it comes to innovation and meeting our sustainability goals. We can only make real steps if we make them together.

Reduce water usage and use only sustainable chemicals in the production process:

- Collaborating with the Cradle to Cradle Products Innovation Institute:

- In 2018, we launched Our Most Sustainable Jeans Ever, combining the cleanest indigo technology in the world, the most sustainable washing techniques, and using 100% organic cotton. A lot of our work through the years was united in this jean and then awarded through a Cradle to Cradle™ Gold Level Certification. We have been building on that innovation ever since and now offer many variations offering the same circular qualities.

- Our recently launched Dyed by Minerals collection:

- We continuously seek new and innovative ways to reduce our impact whilst not compromising style or durability. And in this case, the inspiration comes straight from nature. This unique and environmentally friendly process derives earth pigments and uses them as a natural dye, a common historical practice for centuries already. So we really use nature’s ways to get color instead of something synthetic made in a lab.

- Supporting our suppliers to make sustainable improvements:

- Earlier this year we started a collaborative project in Bangladesh focusing on improving the wet processing at one of our facilities in Bangladesh. Through this project, we aim to actively support the factory to reduce water, chemical, and energy impact. This will not only help reduce the impact of our products but also that of other brands in the same factory.

L:Regarding production practices, do you think denim leaders are using enough eco-friendly materials, reducing the use of water, energy, and chemicals, and optimizing production processes to minimize waste and pollution?

RS: We can always do better. That’s why it is so important to continuously set targets to improve, sustainability is never done. When you use 100% responsible materials you are not at all there yet, there’s so much still to be done in the production process, in transport, in the end-of-life phase. By finding new solutions to reduce and in some cases even eliminate the use of water, energy, and chemicals we can minimize the impact of our products. Through the use of innovations like Smart Indigo and Dry Indigo® we can keep the use of water and chemicals to the minimum and in the end it is all about scaling the use of those innovations. And let’s not forget about durability. Because a sustainably made garment that doesn’t last isn’t sustainable at all.

Dyed by Minerals © by G-Star RAW

L: How do you think installing treatment systems can help the environment? Can you give us an example of this impact?

RS: Having an effluent treatment plant has been a G-Star requirement for years and our suppliers are monitored through rigorous control systems. By applying strict requirements on chemicals that are used in the dye and wash process and when possible, changing to natural inputs we eliminate the risk of harming the environment when the water is released. A clean input leads to a clean output. We are proud to work with suppliers who really see the benefit in investing in sustainable innovations and one part we have seen growing a lot over the last couple of years is water recycling. Some of our suppliers already recycle up to 100% (excluding evaporation) of the wastewater.

L: Do you think denim leaders are encouraging circularity as the planet needs it right now? How important is this for your company?

RS: Circularity is a very important topic for us, and that is why we are proud to work with the Cradle to Cradle Products Innovation Institute. By applying circularity already at the design phase we can create garments that won’t end up in landfills. It is so important to realize that you’re not there yet by just using sustainable fibers, product sustainability is so much more than that. Most negative impact comes from the actual production process, from dyeing and washing, so this is where you can really improve your impact. By working with the C2C Institute together with our partners, we have really been able to learn, improve, and scale response production processes.

Dyed by Minerals © by G-Star RAW

L: Lately, we have been witnessing how fast-fashion and luxury brands are promoting transparency and accountability. What do you think about this? What is your company doing in this regard?

RS: We see it as an important part of our responsibility to share all that we can with our customers (and other stakeholders) on where and how their garments were made. Ever since 2014, you can see exactly where each G-Star garment was put together via the Where is it Made button on the Product Detail Page. We would love to extend that to all supply tiers in the future, right down to the farm. Our extended supply chain is also published on our Raw Responsibility page. The list includes detailed information about every production unit from factory-specific information to worker demographics and sustainability certifications.

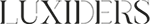

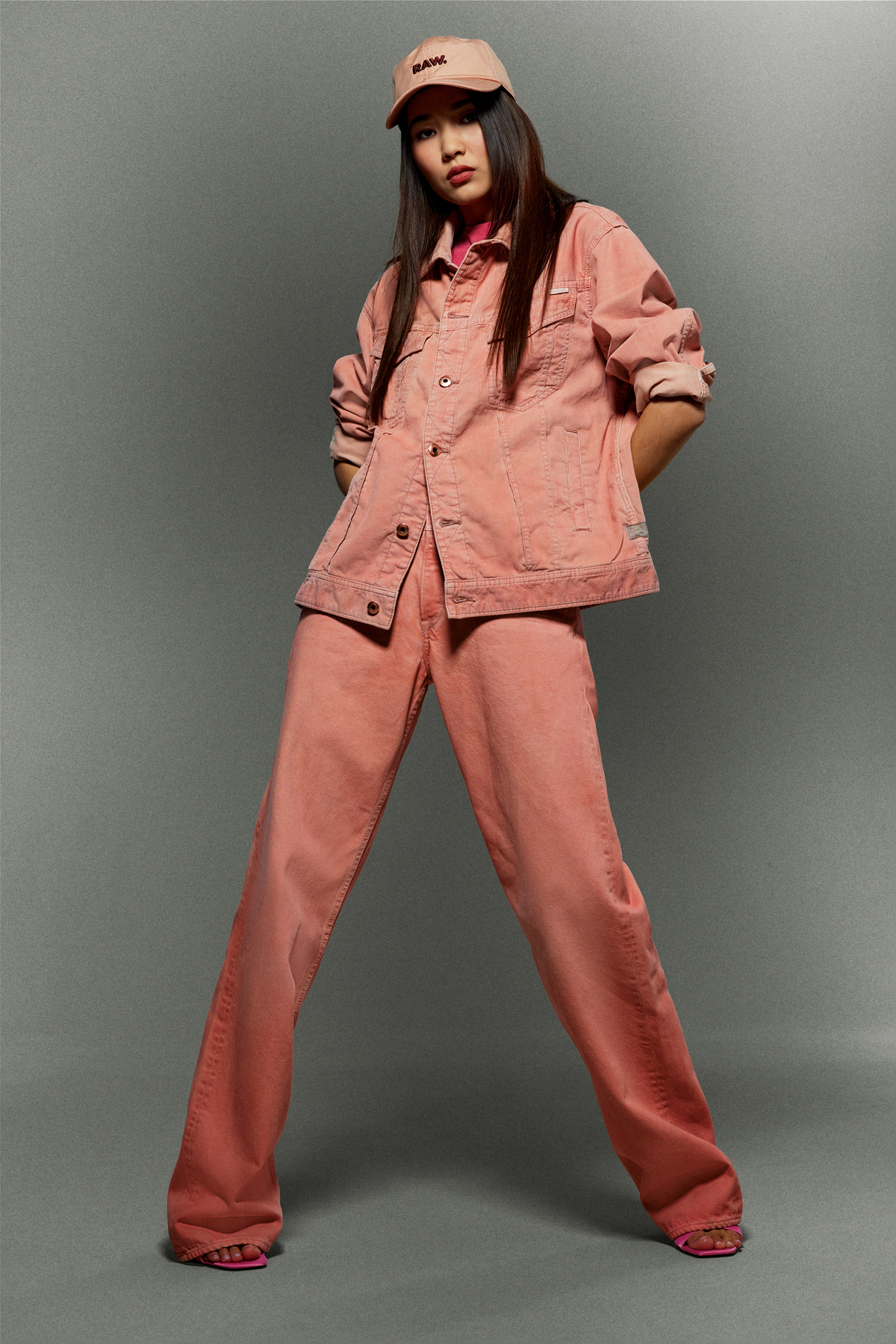

Rola for Dyed by Minerals © by G-Star RAW

The new sustainable capsule launched on 15th May by G-star RAW, Dyed by Minerals ©, takes its name from using naturally sourced color pigments. Like volcanic rocks and soil, the collection embraces these natural hues, and the garments are dyed in cold water which results in saving energy. Made from 75% regenerative cotton and 25% recycled cotton, Cradle-to-Cradle certified denim offers a combination of style and responsibility. The campaign face, Japanese model, and actress Rola confirms this with her motto: “Start doing things that are friendly to both the earth and people.”

Interview:

Tolga Rahmalaroglu

Luxiders Magazine Contributor

From garment production to the washing stage, despite its huge popularity, the denim industry is responsible for a significant amount of pollution and water use. We asked Rebecka Sancho from G-Star about how to achieve a sustainable denim industry.

To receive the Luxiders Newsletter, sign up here.

When Y2K started influencing our lives, we all witnessed several changes in fashion: Low-rise jeans, baby tops, and the rise of the color pink. However, what the 2000s brings else is definitely the double-denim trend. All the influencers, trendsetters, and most of the fashion houses show up with denim pieces nowadays – and this is not only because this garment is trendy, but denim has always been an ‘it’ piece. It is timeless, it is easy to create stylish looks with denim, and it might be the most essential part of post-industrial fashion. Despite this quite anticipated position of denim, the reality behind its production can be very cruel and harmful to the planet. Huge amounts of water use, water pollution in the indigo dying process, and unhealthy working conditions during the sandblasting technique result in denim being produced unsustainably. This is why we asked Rebecka Sancho from G-Star to tell us how they keep their accountability on being sustainable and what denim leaders should consider when producing these beautiful garments.

Rebecka Sancho, Head of Sustainability at G-Star RAW, did her master’s in Sustainable Development at Utrecht University. Focusing on sustainable product strategies, factory improvements, and environmental sustainability; Sancho values innovation in the industry a lot. As G-Star is committed to using recycled, organic, bio-based, and compostable materials to 100% by 2030, here is an interview with the person who is highly active behind these sustainability plans.

50

50

sustainable denim, denim industry, g star, rebecka sancho, organic cotton, sustainable fashion

Rebecka Sancho

L: We all know the denim industry is known for its widespread pollution and negative environmental impacts, which are caused by various factors including the use of toxic chemicals, excessive water consumption, and energy-intensive production processes. What is your company doing to solve these factors?

RS: There’s no denying that the fashion industry is a polluting industry. But people will continue to wear and buy clothes, so the importance lies in discovering how to do things better and scaling it across the industry. Ever since 2006 we have realized our responsibility towards people and the planet and started to integrate sustainability more and more holistically into the core of our business and throughout our value chain. We have policies and targets in place, measure current status and act to reduce any negative impact.

A few examples of our goals and how we work on achieving them are:

In 2023 we will only work with organic, recycled, regenerative, bio-based, and compostable materials.

– Last year, we joined Organic Cotton Accelerator. Being a denim company, we believe it is our responsibility to support sustainable agriculture practices. Through this partnership, we aim to support and scale organic cotton farming, so that not only we can meet our targets, but the entire industry can move towards using more sustainable materials. And because of OCA’s ambitious Textile in Transition project, we can now build direct contact with the farmers, improving livelihoods and tracing our organic cotton right back to its roots.

By 2030, at least 1.000.000 G-Star jeans will be re-used, repaired or recycled.

We are constantly building on and extending our end-of-life phase initiatives:

– If your jeans have lost a button or have a hole or a tear, you can get them repaired at our Certified Tailors, on us.

– As of this Summer our customers will be able to trade-in and buy second-hand G-Star garments on G-Star.com

– If your denim is beyond re-selling or repairing, you can hand them in at our stores for proper and responsible recycling.

Continuously build on and improve the collaboration with our suppliers:

– We recently hosted a two-day supplier conference, where we invited all our suppliers to our HQ office for alignment on strategy and to further improve collaboration. They are pivotal for us when it comes to innovation and meeting our sustainability goals. We can only make real steps if we make them together.

Reduce water usage and use only sustainable chemicals in the production process:

– Collaborating with the Cradle to Cradle Products Innovation Institute:

- In 2018, we launched Our Most Sustainable Jeans Ever, combining the cleanest indigo technology in the world, the most sustainable washing techniques, and using 100% organic cotton. A lot of our work through the years was united in this jean and then awarded through a Cradle to Cradle™ Gold Level Certification. We have been building on that innovation ever since and now offer many variations offering the same circular qualities.

– Our recently launched Dyed by Minerals collection:

- We continuously seek new and innovative ways to reduce our impact whilst not compromising style or durability. And in this case, the inspiration comes straight from nature. This unique and environmentally friendly process derives earth pigments and uses them as a natural dye, a common historical practice for centuries already. So we really use nature’s ways to get color instead of something synthetic made in a lab.

– Supporting our suppliers to make sustainable improvements:

- Earlier this year we started a collaborative project in Bangladesh focusing on improving the wet processing at one of our facilities in Bangladesh. Through this project, we aim to actively support the factory to reduce water, chemical, and energy impact. This will not only help reduce the impact of our products but also that of other brands in the same factory.

L:Regarding production practices, do you think denim leaders are using enough eco-friendly materials, reducing the use of water, energy, and chemicals, and optimizing production processes to minimize waste and pollution?

RS: We can always do better. That’s why it is so important to continuously set targets to improve, sustainability is never done. When you use 100% responsible materials you are not at all there yet, there’s so much still to be done in the production process, in transport, in the end-of-life phase. By finding new solutions to reduce and in some cases even eliminate the use of water, energy, and chemicals we can minimize the impact of our products. Through the use of innovations like Smart Indigo and Dry Indigo® we can keep the use of water and chemicals to the minimum and in the end it is all about scaling the use of those innovations. And let’s not forget about durability. Because a sustainably made garment that doesn’t last isn’t sustainable at all.

50

50

sustainable denim, denim industry, g star, rebecka sancho, organic cotton, sustainable fashion

Dyed by Minerals © by G-Star RAW

L: How do you think installing treatment systems can help the environment? Can you give us an example of this impact?

RS: Having an effluent treatment plant has been a G-Star requirement for years and our suppliers are monitored through rigorous control systems. By applying strict requirements on chemicals that are used in the dye and wash process and when possible, changing to natural inputs we eliminate the risk of harming the environment when the water is released. A clean input leads to a clean output. We are proud to work with suppliers who really see the benefit in investing in sustainable innovations and one part we have seen growing a lot over the last couple of years is water recycling. Some of our suppliers already recycle up to 100% (excluding evaporation) of the wastewater.

L: Do you think denim leaders are encouraging circularity as the planet needs it right now? How important is this for your company?

RS: Circularity is a very important topic for us, and that is why we are proud to work with the Cradle to Cradle Products Innovation Institute. By applying circularity already at the design phase we can create garments that won’t end up in landfills. It is so important to realize that you’re not there yet by just using sustainable fibers, product sustainability is so much more than that. Most negative impact comes from the actual production process, from dyeing and washing, so this is where you can really improve your impact. By working with the C2C Institute together with our partners, we have really been able to learn, improve, and scale response production processes.

50

50

sustainable denim, denim industry, g star, rebecka sancho, organic cotton, sustainable fashion

Dyed by Minerals © by G-Star RAW

L: Lately, we have been witnessing how fast-fashion and luxury brands are promoting transparency and accountability. What do you think about this? What is your company doing in this regard?

RS: We see it as an important part of our responsibility to share all that we can with our customers (and other stakeholders) on where and how their garments were made. Ever since 2014, you can see exactly where each G-Star garment was put together via the Where is it Made button on the Product Detail Page. We would love to extend that to all supply tiers in the future, right down to the farm. Our extended supply chain is also published on our Raw Responsibility page. The list includes detailed information about every production unit from factory-specific information to worker demographics and sustainability certifications.

50

50

sustainable denim, denim industry, g star, rebecka sancho, organic cotton, sustainable fashion

Rola for Dyed by Minerals © by G-Star RAW

The new sustainable capsule launched on 15th May by G-star RAW, Dyed by Minerals ©, takes its name from using naturally sourced color pigments. Like volcanic rocks and soil, the collection embraces these natural hues, and the garments are dyed in cold water which results in saving energy. Made from 75% regenerative cotton and 25% recycled cotton, Cradle-to-Cradle certified denim offers a combination of style and responsibility. The campaign face, Japanese model, and actress Rola confirms this with her motto: “Start doing things that are friendly to both the earth and people.”

Interview:

Tolga Rahmalaroglu

Luxiders Magazine Contributor