Do Organic Leather Alternatives Have a Place in Fashion’s Future?

According to The Vegan Society statistics, “the vegan leather market is set to take over the animal leather market by 2025, by this time it is set to be worth nearly $90 billion” which is a success story for animal welfare. However, The Vegan Society considers synthetic materials ‘vegan’—which they are—but, whilst it causes no harm to animals, this is not the material we should be promoting within the fashion industry.

So what is the material we should be promoting? From rotten mangoes, banana trees and Italian wineries, it is the experimental innovations of organic materials which we are finding very exciting! In a previous post we discussed eight organic alternatives to wool, silk, and cotton, but with increasing developments in leather alternatives, here we discuss the raw materials, manufacturing processes and brands applying these leathers. We have also talked to four of these companies about how they plan to upscale and what the future of these materials could look like; is there a capability for organic materials to actually, fully replace leather?

PINATEX

Piñatex is made from a byproduct of the pineapple harvest in the Philippines; pineapple leaves. Made by Ananas and founded by Dr. Carmen Hijosa in the 1990s, the material is an example of Circular Economy and Cradle to Cradle values, by using a waste product. The pineapple leaves require no additional environmental resources to produce and gives local farmers and communities another sources of income.

After the pineapple is harvested the leaves are collected and the long fibres extracted using semi-automatic machines. These fibres are then washed and dried naturally in the sun, they then go through a “purification process” which results in a fluff-like material. This is then mixed with a corn based polylactic acid (PLA) and undergoes a mechanical process to create the non-woven mesh which forms the base of all Piñatex collections.

The finishing process which takes place in Italy and Spain involves colouring with GOTS certified pigments, a resin which is waster-based and REACH compliant and in the case of Piñatex Performance, a high solid PU transfer coating and a bio-based PU - both REACH compliant. The overall material is made from 80% pineapple leaf fibre and 20% PLA (a vegetable-based plastic material which comes from a renewable source). Although there are elements of plastic and resin coating all of these are REACH compliant which means, no detectable volatile compounds are used within the collection.

In 2015 Piñatex became a certified cruelty-free label by PETA, was the first first raw material to win the Innovation Award and in 2016 won the Grand Designs Green Hero award. It is one of the most well-known alternatives, fit for fashion, accessories and upholstery it is already used by thousands of companies around the world. Piñatex was the chosen material for Hugo Boss’ vegan shoe collection.

MYLO

Bolt Threads is a material innovations company based in California, founded by Dan Widmaier, phd and David Breslauer, phd in 2009. Now, it is comprised of world-class scientists, engineers and innovators.

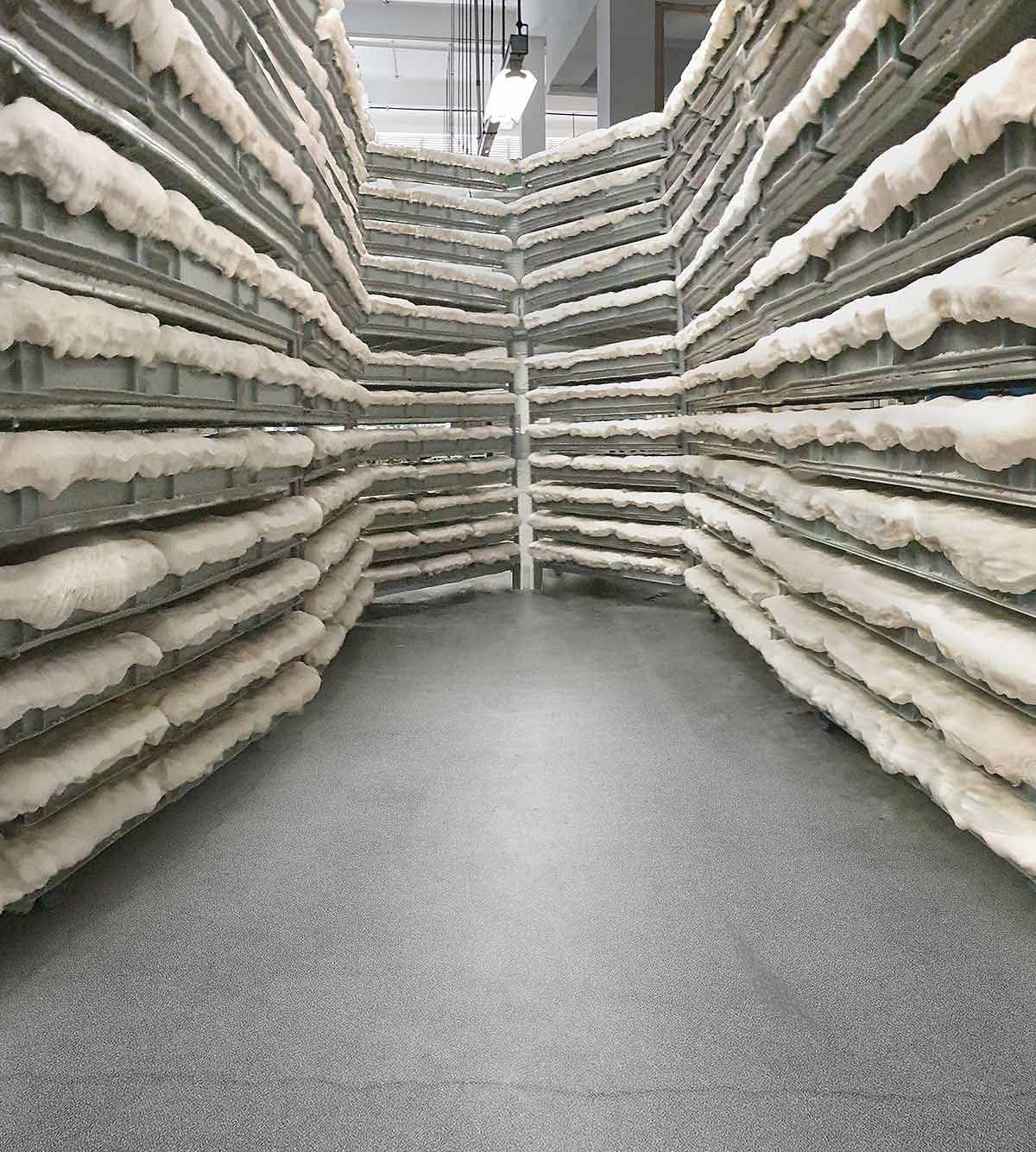

Mycelium is the underground roots of a mushroom and they have been reproducing it’s properties in a laboratory to create Mylo, a certified bio-based material under the German DIN Geprüft standard. To achieve this mycelia cells are fed sawdust and other organic materials on a square mat whilst the humidity and temperature are controlled. The mycelium then grows into a foamy layer, it’s harvested, then processed and dyed into Mylo. When exploring the process Mylo assures us that they have created a supply chain with top certifications in sustainability including a “gold rating from the Leather Working Group” and using only Green Chemistry principles in all their processes. They also plan to undertake a full LCA to measure their carbon footprint and adjust their practise accordingly.

In April 2018 they recreated Stella McCartney’s iconic Falabella bag in Mylo which premiered at the Fashioned from Nature exhibit at the Victoria & Albert Museum in London. But now, Bolt Threads is teaming up with big names in fashion, Adidas, Kering, Lululemon and Stella McCartney, and in 2021 the Mylo Consortium will be available around the world.

GREEN BANANA PAPER

Based in Kosrae, Micronesia, this company manufactures material from recycled banana trunks; the banana trees produce fruit once then dies so, instead of farmers having to abandon them they have been turned into a “one-of-a-kind gift”. The whole tree is utilised—the bananas for eating, the leaves for compost and now the trunk for material. They have recycled over 1 million pounds of banana tree stems!

This is a renewable source as banana trees grow up to 20 feet in just 12 months, so there is a constant supply of raw material after the first and only harvest. Green Banana Paper describes their production process as completely green, the only chemical they use is Soda Ash, which they use to boil down fibres. However, the boiled water is poured into a grey-water tank which neutralises the pH before entering the ground. They admit that although this is an alternative to leather they don’t see it replacing every aspect of leather, such as shoes, Green Banana Paper is only used to create their own wallets.

VEGEA

Vegea was founded in 2016 in Milan by Architect Gianpiero Tessitore and industrial chemist Francesco Merlino with the aim to promote integration between chemistry and agriculture through the development of new eco-sustainable products. Their work mainly involves a collaboration with Italian wineries; the wine waste: grape marc, that is composed of grape skins, stalks and seeds discarded during wine production, have been turned into a material with is 100% vegetal leather.

Vegea produces V-Texiles, V-Polyner and V-Yarn all with slightly different qualities to replace many different fabrics. They confirmed that “no toxic solvents, heavy metals and dangerous substances for humans and the environment are involved in the production process.” Also, all their products are REACH compliant.

Vegea has won the Global Change Award in 2017 and Horizon 2020—the biggest EU research and innovation program ever. However, the company is still in it’s start-up phase and expected to start a mass industrial process in 2022, although in 2019 Bentley announced they have chosen Vegea for the interiors of their new car model and they have worked with H&M for a womenswear capsule collection at the beginning of 2020.

FRUITLEATHER ROTTERDAM

Koen Meerkerk and Hugo de Boon, both designers based in Rotterdam in the Netherlands, founded Fruitleather Rotterdam. With a bachelors degree in spatial design, the duo have focused on how food waste can be used positively.

They have designed a material called, mango sheets. The process is kept largely a secret however, what we do know is the mangoes are de-stoned and shred to a pulp, they are then boiled to kill any bacteria and then spread on a smooth surface to dry. There are some additives used when processing however, they are all made with natural sources.

They are now working at perfecting this process and making it available to more brands, previously Fruitleather Rotterdam’s creations have been featured at Luxtra London.

FRUMAT

Frumat Leather was founded by Hannes Parth, they produce alternative leather from apple cores and skins in Bolzano, Italy. It’s estimated that farmers leave up to 40% of their harvest because they don’t fit cosmetic standards for supermarket. These discarded cores and skins are collected by Frumat and then they are made into a puree, spread on a sheet and dehydrated which when left turns into a leathery sheet. This is combined with Polyurethane to create the final material. The same is done with pulp left from apple juice, which is made into a powder and then combined with pigments and blinders. The end material contains at least 50% apple fibre, and is described as non-toxic and chemical free, 100% biodegradable and approved by PETA. Also, to create this material only energy-saving mechanical processes are used.

In 2018, Frumat won the Technology and Innovation Award at the Green Carpet Fashion Awards and can be found as handbags and trainers in brand such as Luxtra London, Womsh and Breathe360.

MALAI

Founded by material researcher and designer, Zuzana Gombosova and product designer, Susmith C S in 2015, Malai is inspired by the beauty and purity of natural materials, in particular, coconuts. They have developed a process which uses the wasted coconut water from coconut farmers in South India to grow bacterial cellulose.

The process starts with collection of mature coconut water from local coconut processing units, this water is sterilised, enriched with nutrients and fed to a type of bacteria that ferments on it and produces bacterial cellulose. This process takes 12-14 days. After harvest, the Pellicle is enriched with natural fibres from Banana stem, hemp and Sisal plants and refined into a sheet of material, biodegradable natural oil based coatings are applied and a plant based cold-dye bath process for the colouring. The material is a PETA-approved, 100% biodegradable and has no toxic chemicals at any stage of the process.

In February 2020, Malai was announced the winner of the Circular Design Challenge ran by IMG Reliance & UN India for their approach to circular fashion. Malai have many collaborations with brands and designers turning Malai into sandals, bags and bookmarks.

WHAT IS THE FUTURE OF ORGANIC MATERIALS?

According to Satra, a U.K. based independent research and testing organisation, the annual area of leather produced is 19,000 million square feet, which averages around 2 million square feet per tannery. So, we thought we’d ask Malai and Fruitleather Rotterdam a few more questions about their organic projects. They each confirmed the amount of material they could produce, right now, in a year, for Malai was 7874 square feet, and Fruitleather, 3149 square feet. That’s obviously a big difference compared to leather. So what could upscaling these materials mean?

When it comes to upscaling it’s important to remember that many of these projects are based on waste, so there is a possibility of limitations because the amount created is not based on consumer demand and instead is a fixed number. Also, the whole point is to use waste so, for example, planting more pineapples to use the leaves would defeat that purpose, it has to be about using whats on offer naturally. However, when talking to Fruitleather Rotterdam, they confirmed that “45% of of all fruits that are produced for the consumer are eventually considered waste” they added that because of this there are “no limitations and we definitely plan to upscale—the potential to upscale is enormous. The future of Fruitleather is to have a giant factory where food waste isn't seen as waste but as a resource which we can process in a continuous production line.”

Malai agrees that their plans to upscale are not hindered by the amount of coconut waste available and instead is about “adopting a horizontal growth instead of a vertical one - meaning small scale units could be places wherever the raw materials are instead of building large factories.” Finally, Green Banana Paper plan to expand “through offering online educational resources, open-source the how-to and business knowledge, and provide experiential consultation services. We would love to see people using our model around the world.” We have looked at three of the smallest start ups on our list and found that all of them are confident about the prospect of upscaling and are actively researching ways to do that. It turns out that using waste does not limit production as we produce more waste as a society than we can comprehend! Also, even if the numbers never matched that of leather perhaps it is time we change our consumer demands rather than expecting new projects to meet them.

However, it is Mylo, which we believe to be the most prominent figure within the organic material market. Why? When asked about how much they could produce in a year they responded, “the consortium represents demands for hundreds of millions of square feet of Mylo, it can be scaled up infinitely since it is made from a renewable resource, our Mylo production process has been designed to scale millions of square feet of material, which allows us to scale this material to a place beyond a one-off sustainable product.” Bolt Threads is partnering with some of the biggest names in the industry to take their material to the next level, with a renewable source which is found naturally and the process taking place in a controlled laboratory, this is a sustainable material which is ready to take over the market in 2021!

So, do these companies believe that organic materials could ever replace leather? Green Banana Paper definitely thinks so, “yes, absolutely, there are so many promising new vegan 'leather' companies compared to just a few years ago. Natural fibres and food waste are the 'super' materials we must utilise to move away from so much unnecessary cruelty and pollution.” However, these materials are not developed to be identical to leather, there will always be differences in the way they look, how workable they are or resistant they are. On that note Malai offers an interesting sentiment; “it’s important to recognise the fact that leather might not necessarily be replaced by another single material. We will most likely see an array of different types of leather replacements each suitable for a different type of application where we currently see leather.” We need to embrace all of these projects in order for us to fulfil the need for a true and dependable replacement.

But, isn’t just about finding a replacement for leather, whilst some of these materials have a striking resemblance, there are many other reasons for their development. These materials show how we need to adopt a circular economy. They are showing us how we can not only replace leather and synthetics but how we can replace our attitude and harmful habits within many industries.

We are now seeing a very exciting time where, in a few years, these materials could be in the mainstream market. Rather than just being considered small start ups and limit edition collections, we could actually see them having a big affect on the industry. All of these companies have spent years developing very precise materials and now, it’s simply about being able to offer that material to more people. Right now, it’s all about seeking these materials out and supporting them, if we want organic materials to take over the industry then we must show our interest as a consumer.