All The Answers About Sustainability In Fashion | Première Vision 2023

Turning adversities into opportunites. The last edition of Première Vision drew a rainbow through the clouds. A majestic Eco-Innovation Forum showed all the stories we wanted to watch, through numerous responsible material and textile innovations from fashion's top leaders. We are still at the beginning of progress. But the future is hopeful.

To receive the Luxiders Newsletter, sign up here.

It is becoming increasingly difficult to classify sustainable fashion, and worse, to differentiate it from non-sustainable. The very generalised and inaccurate definition of the word "sustainability" and its indiscriminate use as a marketing and greenwashing tool is unmanageable. Lack of information or masked information is slowing down and even stopping the process of change that the world's second most polluting industry, the fashion industry, mandatorily needs.

PREMIERE VISION SHEDS LIGHT ON THE SHADOWS

With thousands of questions we arrived at Première Vision, the world's leading trade fair for fabrics and textile materials. The organisation counts with the world's leading experts in textile materials and fabrics and we met them during our visit. They shed light on the doubts that textile and, especially fashion designers, as well as fashion journalists, have at the moment.

Ariane Bigot, Associate Fashion Director of Première Vision, understands well our anguish when it comes to assessing fabrics, which are never defined by her as sustainable, but as recycled, regenerative, organic... Instead of using such a general and ambiguous term, the term is always clear and not general. We like it.

Our half-hour meeting turns into an intense hour-and-a-half talk in which Bigot explains how to act in case of doubt, which fabrics or materials are really revolutionising the transition to responsible fashion and what other elements we have to take into account when using the word sustainability.

"It is the beginning of the progression" - she start saying - "The evolution is coming slowly. There is nothing really surprising, something completely new. The fashion industry is looking for something completely new and revolutionary, but the processes need time to change. Now in recycled polyester we have fancy alternatives, like jacquards, guipure, laces...,and in embroideries of recycled sequins. This is new, but recycled polyester is not new, it is in evolution. Other example, in the begining recycled polyester was really rude, hard to treat. Now it is very difficult to see even the difference between recycled and new polyester".

© Courtesy by Premiere Vision

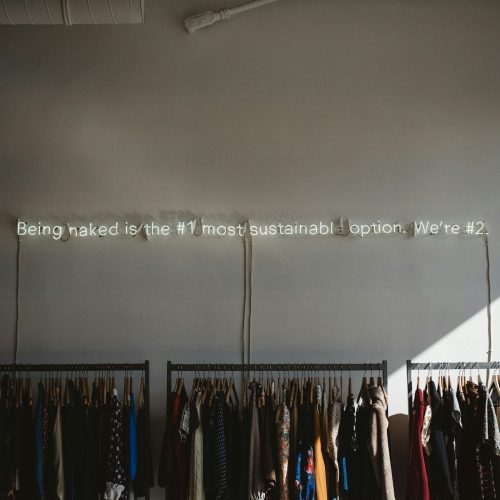

The Evolo process recycles chrome-tanned waste leather and transforms this solid residue into liquid solution that can be used for retainning without additional chrome. Leather by Sciarada Industria Conciaria, from Italy.

This material was developed with a fibre made from 33% recycled leather residues, mixed with Lyocell. By Boshin Textile, Korea.

Many developments have highlighted the circular approach to raw materials, with the repurposing of textile, agri-food and cosmetics residues. These can optimize resources to reduce the pressure on arable land and diversify sources.

.

© Courtesy by Premiere Vision

WELCOME TO THE ECO-RESPONSABLE TRANSFORMATION

The eco-responsible transformation of the industry can be felt at every stage of the value chain. The use of waste for the creation of new materials and also for dyeing, and traceability continue to gain momentum, from sourcing to measuring social and environmental impact. Also the dyes, printing and finishing stages are aligned with environmental management criteria to reduce the impact of water, energy, gas emissions, chemical substance usage and waste volume.

The Smart Creation space at the Première Vision Paris show, exhibited the industry’s most committed, inspiring and even visionary companies. There we found eco-designed, organic or recycled materials; sustainable finishings and treatments (dyes, treatments, prints); innovative and responsible design and production processes; products and technological solutions facilitating eco-design and traceability; global circular approaches; and more. On the other hand, the Eco-Innovation forum launched a cutting-edge selection of the show’s creative and responsible offer to promote the sustainable products, developments and approaches of companies exhibiting there.

"To become more sustainable it is not enough to offer an environmentally friendly and certified product, it is about looking at the whole company and its processes from an eco-conscious perspective." - says Ariane Bigot, Associate Fashion Director at Premiere Vision. Limited water consumption, effluent quality, control of chemical inputs, mindful energy consumption, managing air emissions and water, being attentive to the health and safety of workers and animal welfare must be in the focus.

Erica Industria Tessile, from Italy

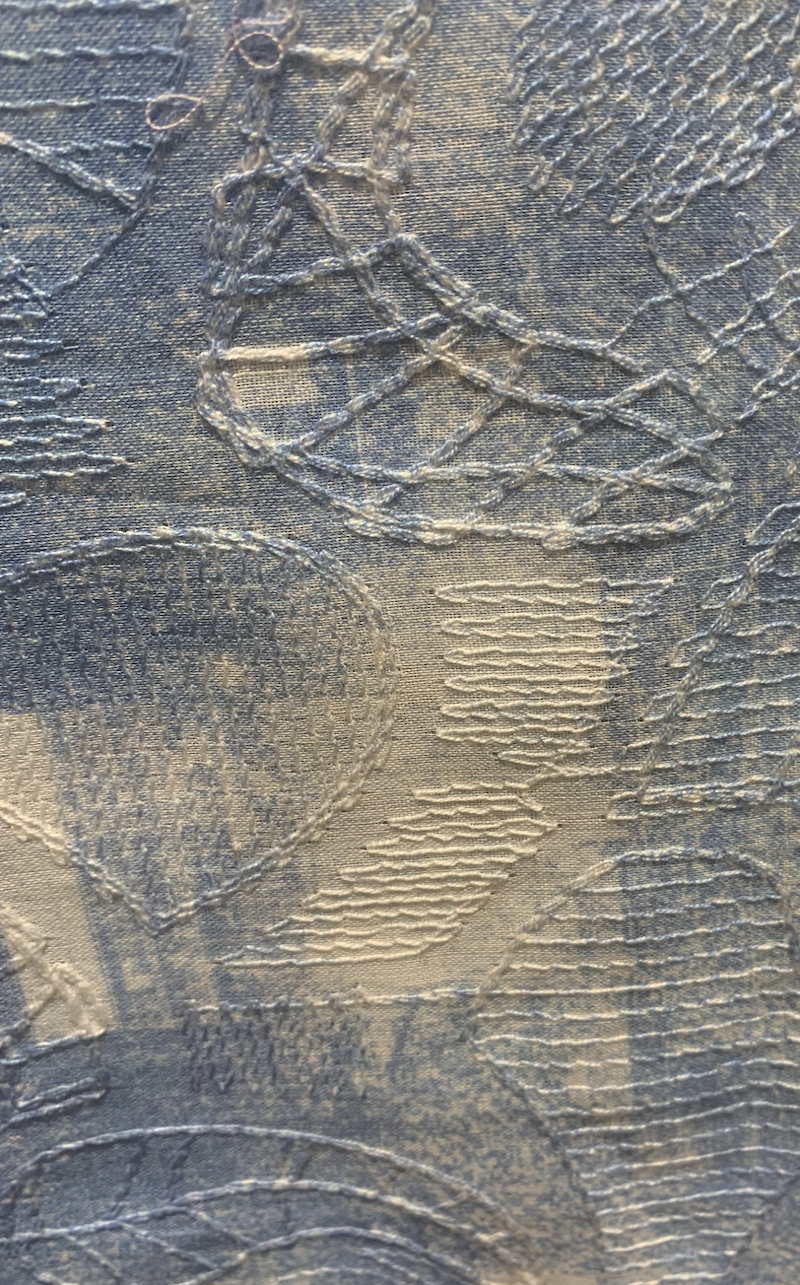

Hoh Hoferhecht Stickereien from Austria. Sedatex from Spain.

Waterless, Recycled, Low Chemical impact finishing and traceable textile by Shanghai Skytex, from China.

Organic, traceable, low chemical impact finishing, waterless textile by Recyctex, from China.

Recycled, traceable and organic textile made from orange waste by Tearfil Textile Yarns, from Portugal.

Made out from hemp, by Acatel-Impetus Group, from Portugal.

NOVELTIES IN FABRICS

Viscose with FSC Certification

Among the new materials we discovered, FSC-certified viscose stands out, which now allows the creation of satins and lace using cellulose fibres from FSC-certified wood.

From Waste to Cellulosic Textiles

- Naia Renew, in this sense, deserves our attention. It is a low-impact cellulose figure, sourced from 60% sustainability managed wood pulp and 40% certified recycled plastic waste. It has both FSC (Forest Stewardship Council) and PEFC (Pan European Forest Certification). Naia produces fluid knitted fabrics with a slight iridescent sheen.

- Refibra combines 30% pre- o post-consumption recycled textiles and 70% wood pulp from sustainably managed forests.

- Circulose, obtained exclusively by the chemical recycling of pre- or post- consumption cotton, from production offcuts of clothes at the end of their life.

- Regino, regenerated linen residues into artificial fibre.

Pla. Bio-Sourced polylactides

We also found a diversification of developments using bio-sourced polylactides made from corn, beet or sugar cane residues, for use in silks or ready-to-wear knits. The eco-hybrid Solotex, a highly elastic fibre designed with a blend of bio-based PTT containing 40% plant-based raw materials and recycled PET, stands out in this section.

Bio-Sourced Membranes

This is another major breakthrough. "It can put an end to the problem of microplastics," says Bigot. Virtuous compositions of membrane fabrics, with a base of recycled polyester or biodegradable polyester and a bio-sourced polyurethane membrane, with waterproof, breathable or wind resistant properties.

Bio-Sourced Coatings

They reduce the chemical impact through the use of water-repellents with olive oil or bio-based coating.

Recycled Noble Materials

Also important is the trend towards the use of recycled noble materials derived from animals: 90% al 100% de silk, camel wool or cashmere content in blends, used for knitted and woven fabrics. Recycled schappe silk is made from the waste accumulated during spinning or weaving.

Regenerative Cotton

Regenerative farming techniques are an amazing solution. They include no tillage and no application of synthetic chemical inputs, implementation of crop rotations and cover crops that improve soil nutrient status, and sustainably managed grazing. These practices restore soil fertility, improve water retention and preserve biodiversity. Organic farming imposes rules for cultivation, whereas regenerative agriculture has a results-based focus, and its practices may differ.

Recycled Syntethics

With the goal of cleaning the oceans, the challenge of recycled synthetics is transforming the fashion industry. After meeting Seaqual, a polyester made from recycled marine litter and PET bottles; Econyl, a regenerated polyamide made from recycled fishing nets; and Repreve, made from bottles collected in the ocean, within 50 km of the coast; we say hello to other sources:

- NewLife, a traceable recycled polyester filament, obtained through the mechanical recycling of PET bottles, with no chemical addition. It is GRS-certified.

- Q-Nova, a recycled polyamide with no chemical additives, made from more than 50%of pre-comsumption waste.

- Q-Cycle, a polyamide developed through chemical recycling. It can use waste that cannot be mechanically recycled, such as end-of-life types, by transforming them into pyrolysis oil to replace the fossil resources used for conventional polyamides.

- Seawool. Polyester made from recycled PET bottles combined with a fine powder of crushed oyster shells, offering antibacterial properties, breathability, and thermoregulation.

"If your recycle cotton, you have to separate the fibers, the fibers get broken and so, the quality of the upcoming cotton loose quality. So for jeans or t-shirt it is fine. But for high quality garments, you need to use new cotton" - this is one of the advices Ariane Bigot, Associate Fashion Director at Premiere Vision, underlines.

Undyed cotton from post-consumer denim for new denim fabrics, jacquards or knits. By Ecosimple Sustainable Fabrics, from Brazil.

THE RISE OF NATURALS

For a long time, linen, hemp, nettles and kapok have had a discreet market presence. Their inveronmental performances have enabled them to make a comeback. They now blend in with all kind of composition to create varied end products, enlivened by bright colours. All of them assure economic use of water, minimum imputs, crop rotation, carbon sink and zero waste.

- Kapok is drought resistant and requires little water. It is insulating and naturally water repellent.

- Cork. We have seen yarns using cork residue combined with cotton to add texture to marl yarns.

- Nettle is a long fiber extracted from the stem of the plant. Its growth requires little water, is fast and allows up to 5 harvests per year. It absorbs dyes very well, is resistant and brings fabrics a crunchy aspect.

- Soybean. We have seen a protein fiber derived from soybean by-products, transformed with a non-toxic, solvent in a closed loop process.

- S-Café ® is a technology using coffee grinds blended with polymers, Cradle to Cradle and Bluesign certified.

- Orange fiber. Another technology based on the extraction of high-quality cellulose from the lelfovers of the citrus fruit juice industry, representing 60% of the initial weight of the processed fruit.

- Hemp. Cultivated in soil rotation, it cleans and strengthens the soil for the next crops. It requires little water and phytosanitary imputs. This zero waste plant is fully valorized and is an excellent carbon sink.

- Abaca is a banana fiber, extracted from the leaves. Its culture requires only rainwater, no pesticides or fertilizers.

- Pinayarn or Pinacell are based on the extraction of pineapple leaf fibres, an agricultural waste product, with resistant properties.

- Agraloop TM is using banana, pineapple, hemp or linen residues. Using responsible production that recycles water. The only effluents are organic amendments returned to the farmers for soil regeneration. The sub-products are used to make paper, bio-composites for construction, or for bio-energy to supply the factory.

- Seacell TM, artificial fibre made from seaweed and wood pulp from sustainably managed forests using a process with a reduced chemical impact.

- Ecovero TM, a viscose fibre, sourced from sustainably-managed and FSC-certified forests, optimized processing and FSC-certified.

NATURAL DYES EVOLVE. FROM WASTE TO FABRIC

The Spring-Summer 2024 color range encourages us to discover a variety of options and solutions, balanced between dream and reality.There is an evolution in natural dyes, made out of plants (indigo, genet) or fruits (Japanese plum), or Nano Earth dye technology with minerals. They provoque color ranges from pale to saturated tones, processes without tonic mordant, used on natural plant and animal fibers (cotton and silk) and cellulosic fibers (viscose and lyocell)

The novelties come from food dyes made from food waste: matcha tea, rooibos tee, and coffee. Also from the use of the natural colours of animal hair and plant fibres, in their range of white, greys and browns. In this case, it is very important the strict control of substances used and pigments coming from recycling, machines and technologies enabling greater colour absorption, reduced water and energy use and the generation of fewer effluents. As new technologies, we love:

- COLOURIZD™ , a dyeing technology for cellulosic fibres, acting on the molecular structure of the cellulose to enable better dyeability, without bleaching the yarn before coloration, and saving 98% of water compared with traditional procedures, thus drastically reducing effluents.

- Nano Earth dye uses non-toxic minerals with a nanotechnology that can permeate the colouring in the heart of the fibre, for an optimal use of the pigments and a reduction in the effluents to treat. There are fewer stages in the coloration process than in the conventional techniques for obtaining reduced water and energy consumption.

Recycrom® develops pigments using textile residues, worn-out clothing and production offcuts, processed into an extra-fine coloured power that can be used on cotton and plant fibres, wool, and polyamide. Easier to filter, this pigment colouring requires minimal wastewater treatment.

New plant-based dying processes, using fruits, flowers, plants or agri-food vegetable residues to dye, without the use of toxic mordants, in a wide range of colours and stand the test of time and use.

The Colorifix® technology is based on microbiology and on replicating DNA as it is found in nature in order to produce pigments. The fermentation of agricultural by-products can be used to create colorants thanks to the action of micro- organisms whose DNA contains enzymatic colour catalysts.

Made from Nettle, long fiber extracted from the stem of the plant. By Migra Since 1988, from Italy.

+ Words:

Belvis Soler

Luxiders Magazine